Contact Process

Sulphuric Acid is Manufactured in Industry

- Sulphuric acid, H2SO4 is manufactured in the industry through Contact Process.

- The raw materials used are sulphur, air and water

- The Contact process consists of four stages.

Stage 1

- Molten sulphur is burnt in dry air to produce sulphur dioxide

- The gas produced is then purified and cooled.

S + O2 → SO2 - Sulphur dioxide can also be produced by burning metal sulphides such as lead(II) sulphide or zinc sulphide in dry air.

2PbS + 3O2 → 2PbO + 2SO2

Stage 2

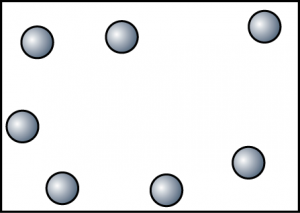

- In a converter, sulphur dioxide and excess oxygen are passed through vanadium(V) oxide.

- vanadium(V) oxide act as a catalyst to expedite the process.

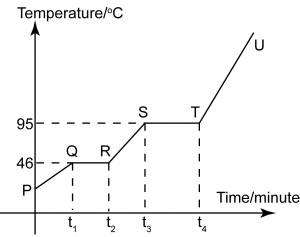

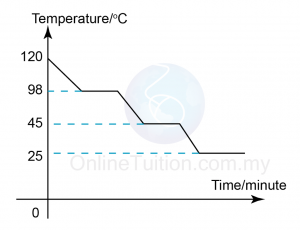

- The optimum condition for the maximum amount of product are as follow:

- Temperature: 450 – 500 °C

- Pressure: 2 – 3 atm

- About 99.5% of the sulphur dioxide, SO2 is converted into sulphur trioxide, SO3 through this reversible reaction.

Stage 3

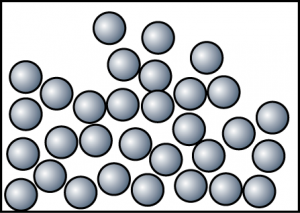

Sulphur trioxide is dissolved in concentrated sulphuric acid to form oleum (H2S2O7).

SO3 + H2SO4 → H2S2O7

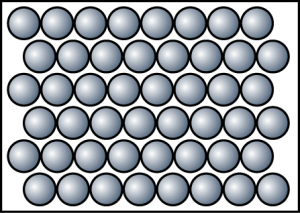

Stage 4

The oleum, H2S2O7 is then diluted with water to produce concentrated sulphuric acid, H2SO4 in large quantities.

H2S2O7 + H2O → 2H2SO4

Note:

- The two reactions in the third and fourth stages are equivalent to adding sulphur trioxide, SO3 directly to water.

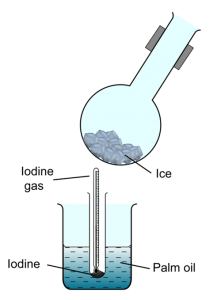

SO3 + H2O→ H2SO4 - However, this is not done in the industry because sulphur trioxide, SO3 reacts too violently with water.

- This produces a lot of heat and a large cloud of sulphuric acid, H2SO4 mist.

- The mist is corrosive, pollutes the air and is difficult to condense.